In the world of manufacturing and production, efficiency is king. Companies that optimize operations while upholding high-quality standards thrive. Packaging plays a crucial role for businesses involved in high-volume production. The packaging process can either be a bottleneck that slows everything down or a well-oiled machine that keeps everything running smoothly. If you aim to increase efficiency and reduce costs, rollstock packaging is the ultimate solution.

The Efficiency Advantage of Rollstock Packaging

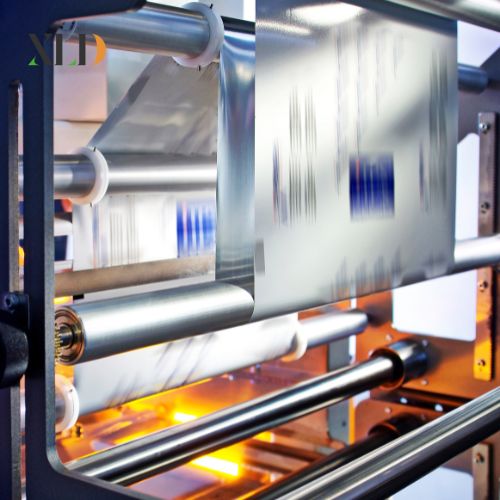

Rollstock packaging is designed for speed and efficiency, making it ideal for businesses that need to pack large quantities of products quickly. This method involves large rolls of film fed into a machine, which then forms, fills, and seals the packaging in one continuous process, reducing manual labor and speeding up packaging time.

For high-volume production lines, the benefits of rollstock packaging are clear:

Faster Production Speeds: Rollstock packaging machines are capable of operating at high speeds, significantly increasing the number of units that can be packaged per minute.

Reduced Downtime: With fewer manual steps involved, there’s less room for errors or delays. This keeps your production line moving smoothly, ensuring you meet your deadlines.

Lower Labor Costs: This content reads as if it is human-written.</p>">Automation reduces the need for workers to oversee packaging, cutting labor costs and allowing the team to focus on other critical areas of production.

Cost-effective and Flexible Packaging Solution

One of the biggest challenges in high-volume production is managing costs. packaging materials, labor, and storage can quickly add up, eating into your profit margins. Rollstock packaging offers a cost-effective solution that addresses these concerns.

Material Savings: Rollstock film is often cheaper than pre-made pouches or bags. You also buy it in bulk, which further reduces the cost per unit.

Minimized Waste: Because rollstock packaging is formed to fit your products exactly, there’s less excess material, leading to less waste. This not only saves money but also supports your sustainability goals.

Versatility in Design: Rollstock film can be customized to include various features such as resealable zippers, tear notches, or even unique shapes that make your product stand out on the shelf.

Enhanced Product Integrity and Shelf Life

In high-volume production, maintaining product quality is essential. Rollstock packaging not only supports efficient production but also helps preserve the integrity and freshness of your products.

Consistent Sealing: Rollstock machines provide precise, consistent seals that reduce the risk of leaks or contamination, ensuring that your products remain safe and fresh until they reach the consumer.

Barrier Protection: Rollstock films can be designed with advanced barrier properties to protect against moisture, oxygen, and other elements that can degrade product quality over time.

Brand Visibility: High-quality printing options allow for vibrant, eye-catching designs that enhance your brand’s visibility and appeal to consumers.

Why XLD Packaging’s Rollstock Solutions Stand Out

At XLD Packaging, we understand the unique challenges of high-volume production and are committed to providing solutions that help your business succeed. Our rollstock packaging solutions are designed to meet the demands of large-scale operations while ensuring cost efficiency, product integrity, and environmental responsibility.

Customized Rollstock Materials: We offer a wide range of rollstock films, including eco-friendly options, to match your specific product needs and sustainability goals.

High-Performance Machinery: Our rollstock machines are engineered for reliability and speed, ensuring your production line remains efficient and productive.

Expert Support: With XLD Packaging, you’re not just purchasing packaging materials—you’re gaining a partner. Our team of experts is here to help you optimize your packaging process and ensure your rollstock solution is perfectly tailored to your operation.

Conclusion: Transform Your Production Line with Rollstock Packaging

For businesses involved in high-volume production, efficiency, cost-effectiveness, and product quality are paramount. Rollstock packaging provides the ultimate solution, offering speed, flexibility, and reliability that traditional packaging methods simply can’t match.

By integrating rollstock packaging into your production line, you can streamline your operations, reduce costs, and maintain the high standards your customers expect. And with XLD Packaging as your partner, you can be confident that you’re getting the best possible solution for your business.

Take the next step toward transforming your packaging process with XLD Packaging’s rollstock solutions. Contact us today to learn more about how we can help you achieve your production goals and drive your business forward.